"Zachary Oberle" (zacharyoberle)

"Zachary Oberle" (zacharyoberle)

07/26/2016 at 12:55 • Filed to: Project Hoondy, Cusco, WPC, DIY, Pornography

9

9

7

7

"Zachary Oberle" (zacharyoberle)

"Zachary Oberle" (zacharyoberle)

07/26/2016 at 12:55 • Filed to: Project Hoondy, Cusco, WPC, DIY, Pornography |  9 9

|  7 7 |

The time had come. Our Cusco RS differential was back from

!!!error: Indecipherable SUB-paragraph formatting!!!

in California. We lined up time off work and made an appointment with our mechanic. All we had left to do was assemble our monstrous LSD, assisted by the

extremely

vaguely

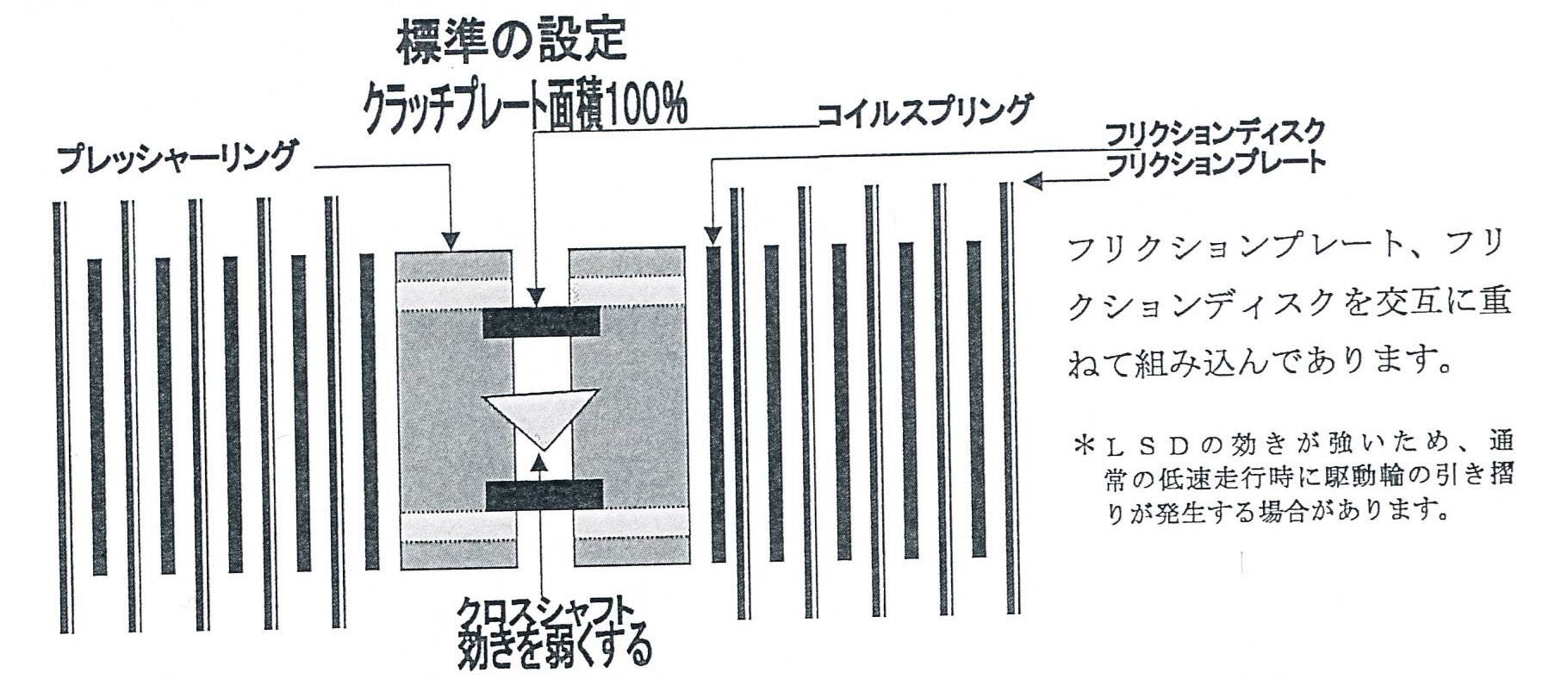

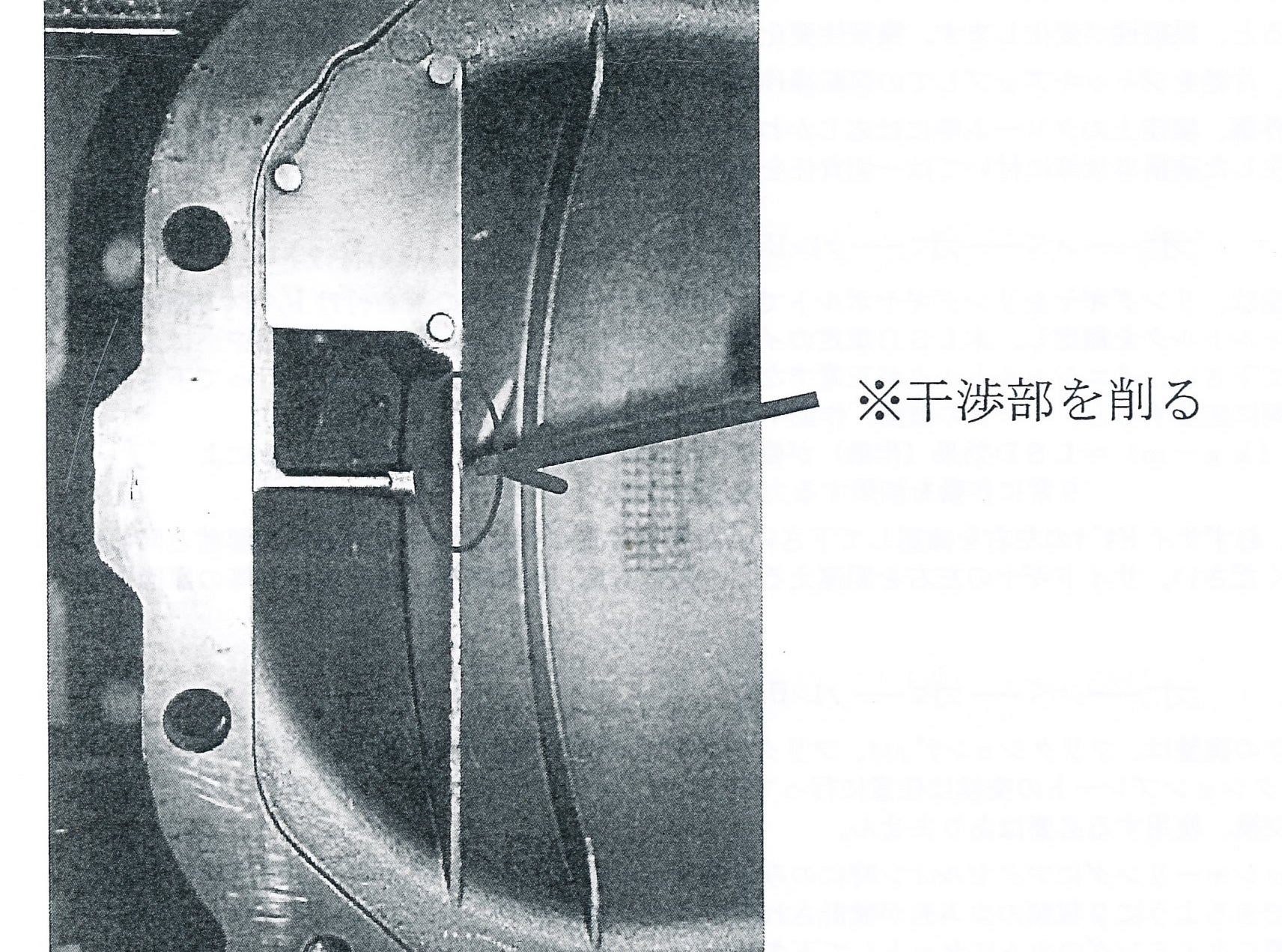

helpful Japanese-only installation guide:

Uh-huh.

Yeap.

Great.

Ooo! That looks ominous. Wonder what it means.

Hey, check this bit out! We hope Uncle Izumi didn’t report us to the Japanese authorities... nah, he’s too cool for that.

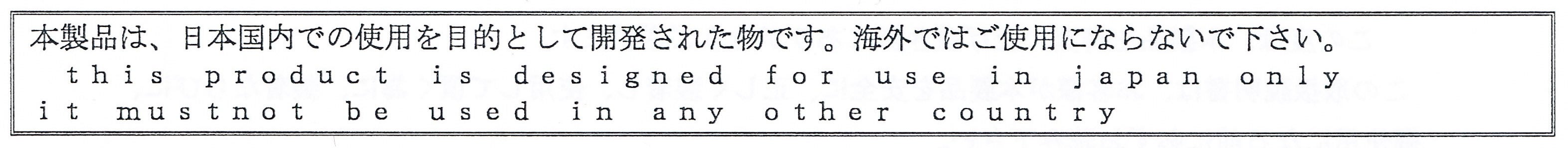

Thankfully, we aren’t the only English-speaking folks to have had a crack at one of these things. The super-nerds at MotoIQ are big proponents of the Cusco RS. In fact, their !!!error: Indecipherable SUB-paragraph formatting!!! was one of the main deciding factors that pushed us over the edge into splurging on this deluxe LSD.

That said, we want different things out of a diff for Project Hoondy as compared to MotoIQ’s own !!!error: Indecipherable SUB-paragraph formatting!!! They desired ultimate lap-times on a road course and therefore deactivated a pair of clutches. This, combined with low spring tension, made their Cusco RS relatively soft, allowing less lock-up under hard throttle so that their car could best “find” grip on corner exit.

We want Project Hoondy to be an all-rounder, with more emphasis put on fun than lap times. This means we’re looking for some aggressive lock-up to make our car a bit tail-happy when on power. This will make the Gencoupe slower around a road course than it ultimately could be, but in exchange should be much more of a hoot to drive.

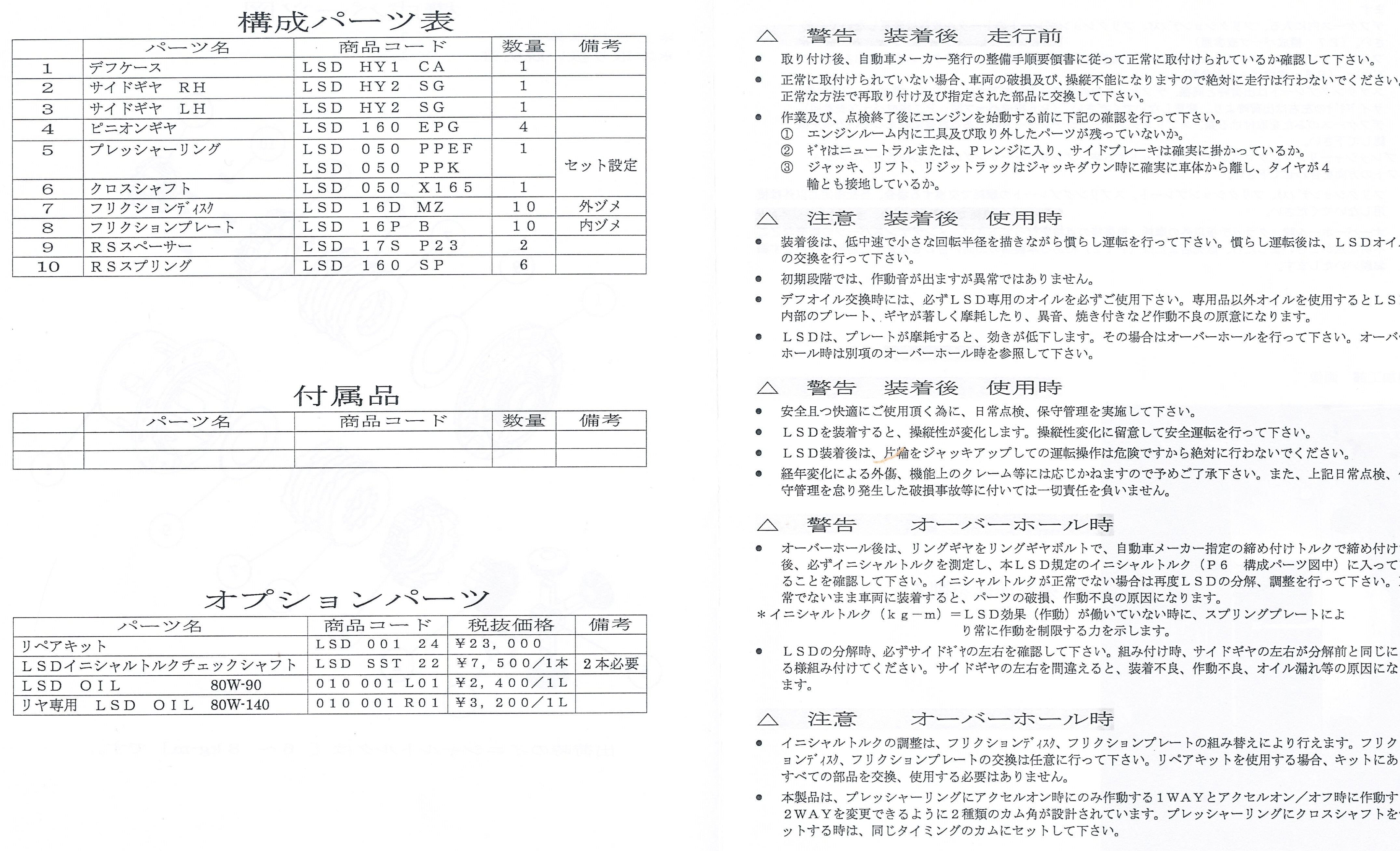

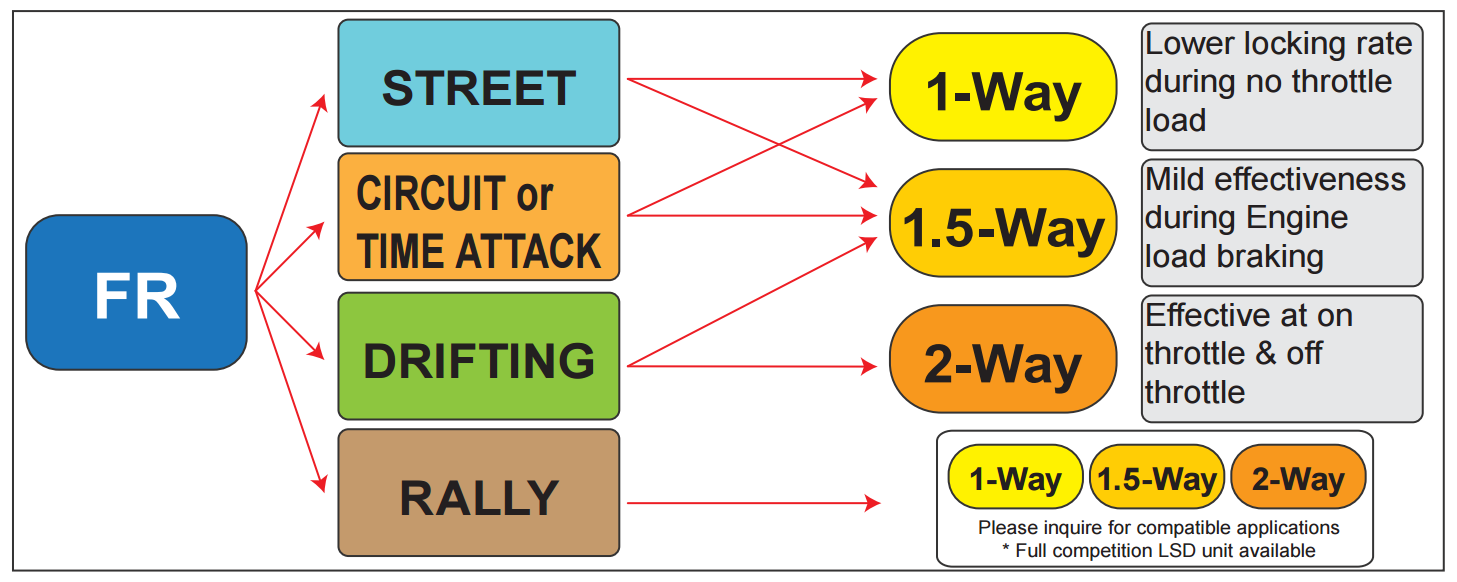

We waffled a bit on how exactly to achieve this. The Cusco RS is highly adjustable, with three ‘dials’ to play with. The cam profile of the cross shaft can be oriented differently in the center section in order to choose between 1.5-way and 2.0-way locking action.

©Cusco USA

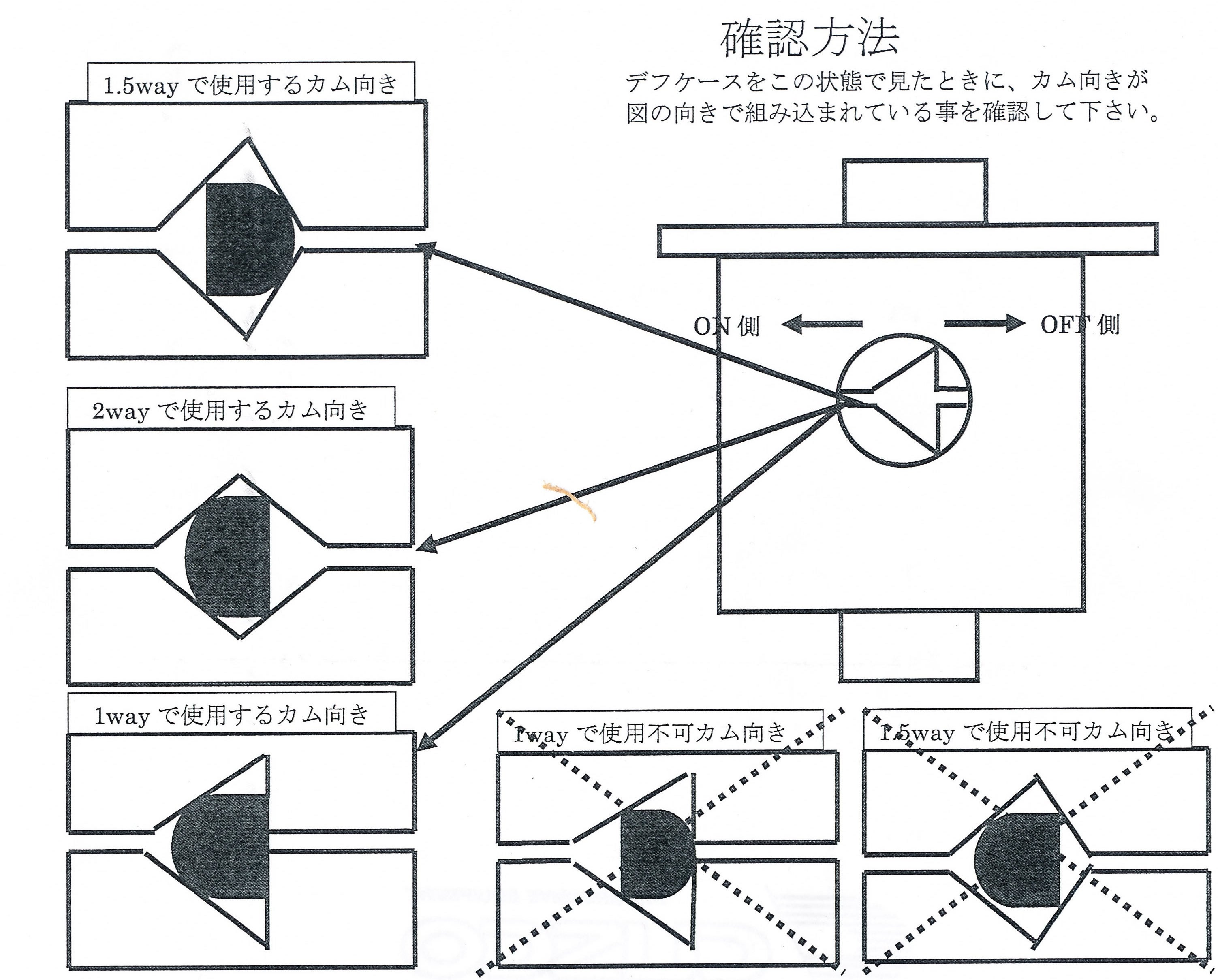

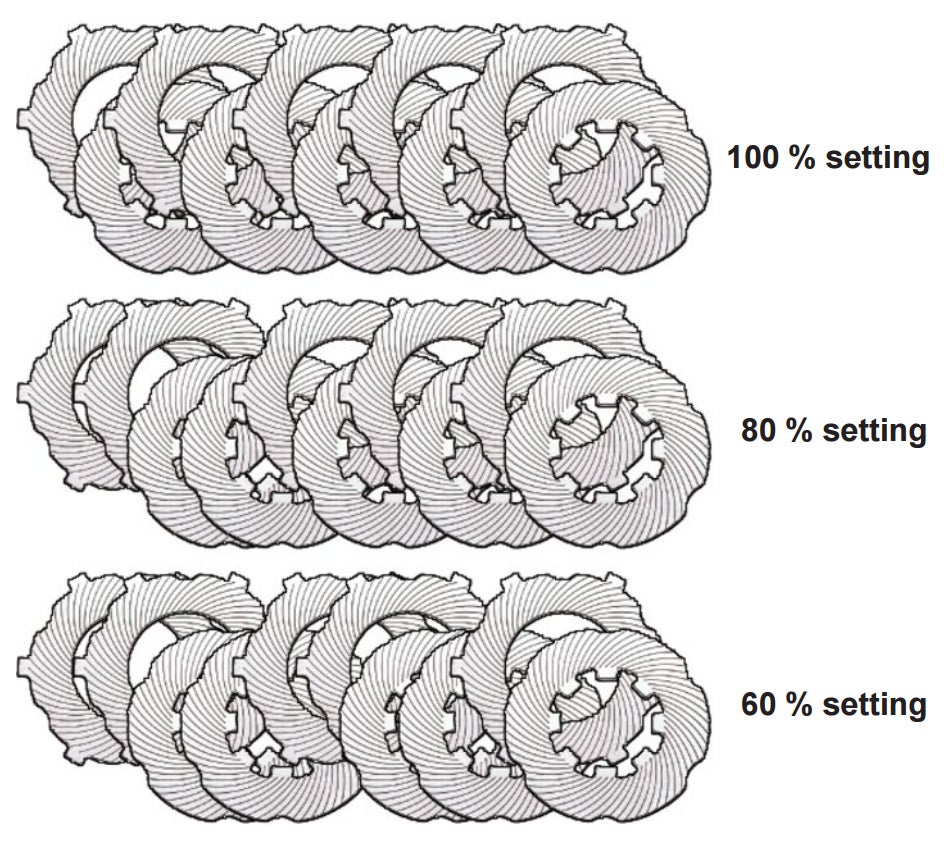

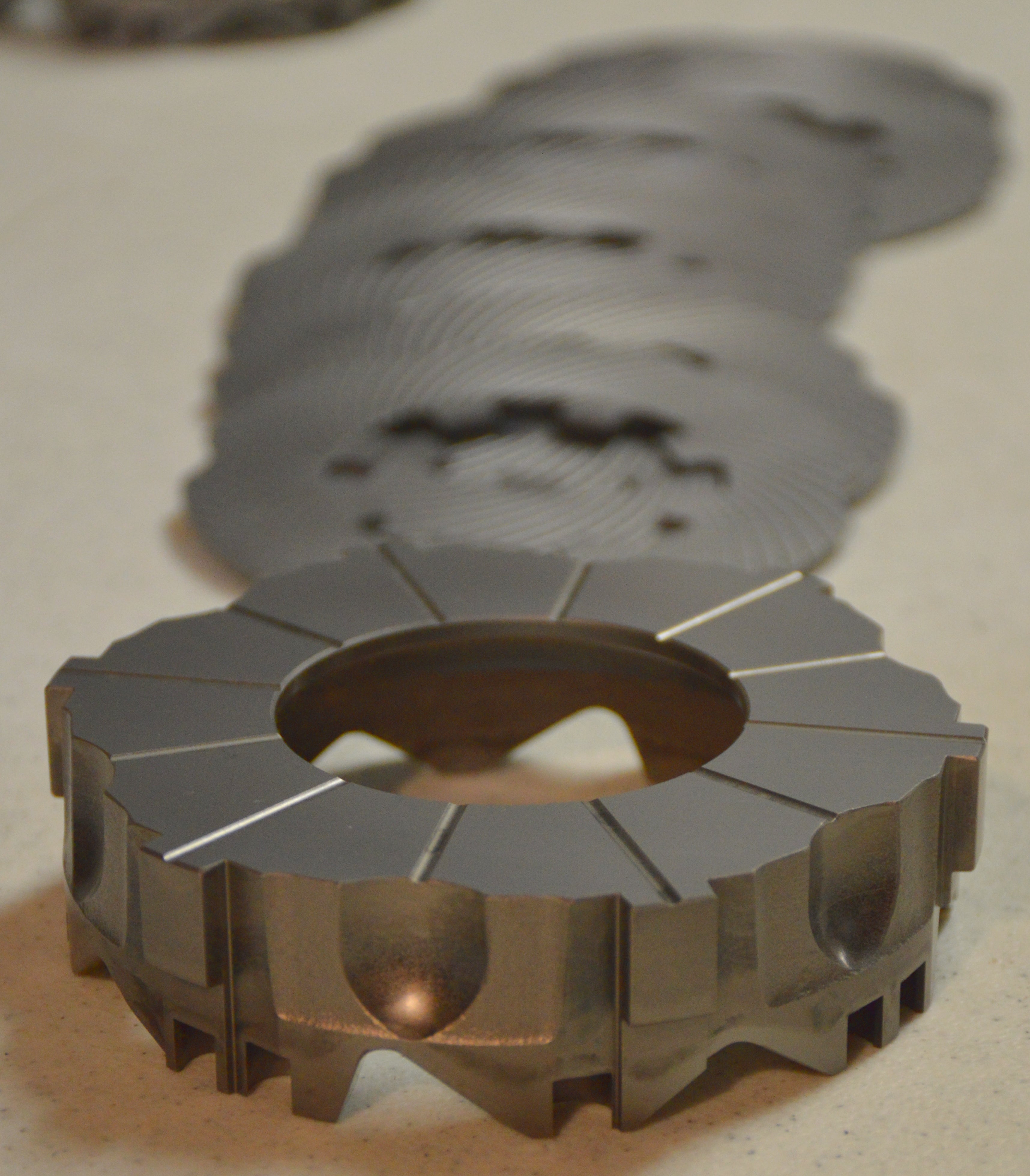

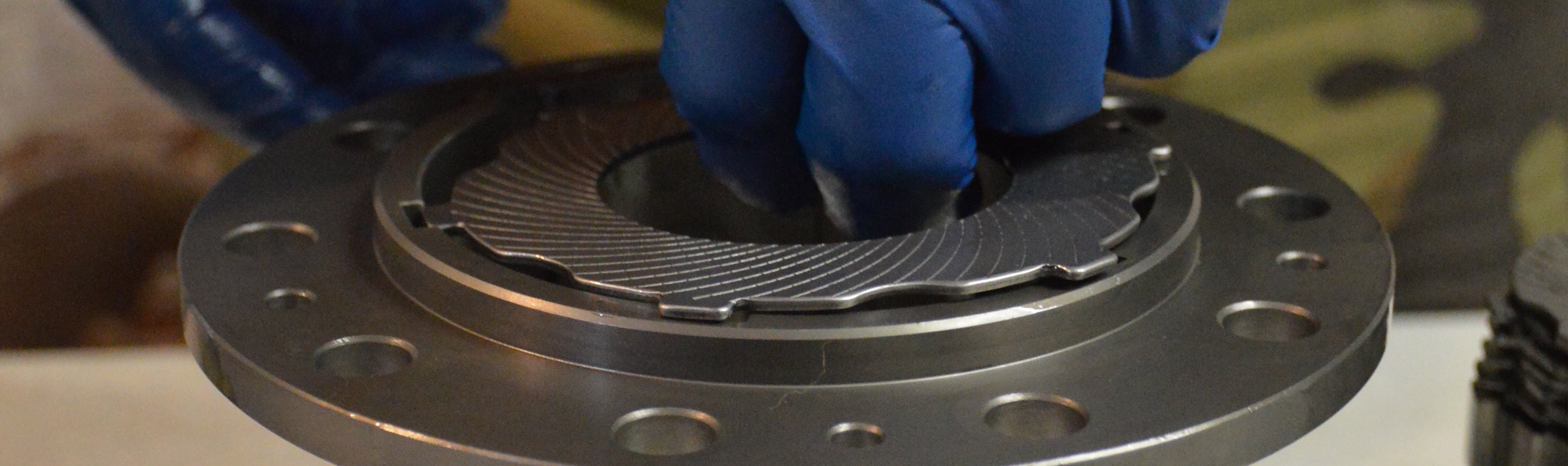

There are twenty clutch disks in this differential, but they don’t all need to be used. Drive and driven clutches can be doubled up to deactivate them, providing less ultimate locking force. This puts a ceiling on the diff’s locking potential, ensuring that it can’t fully lock the rear wheels together.

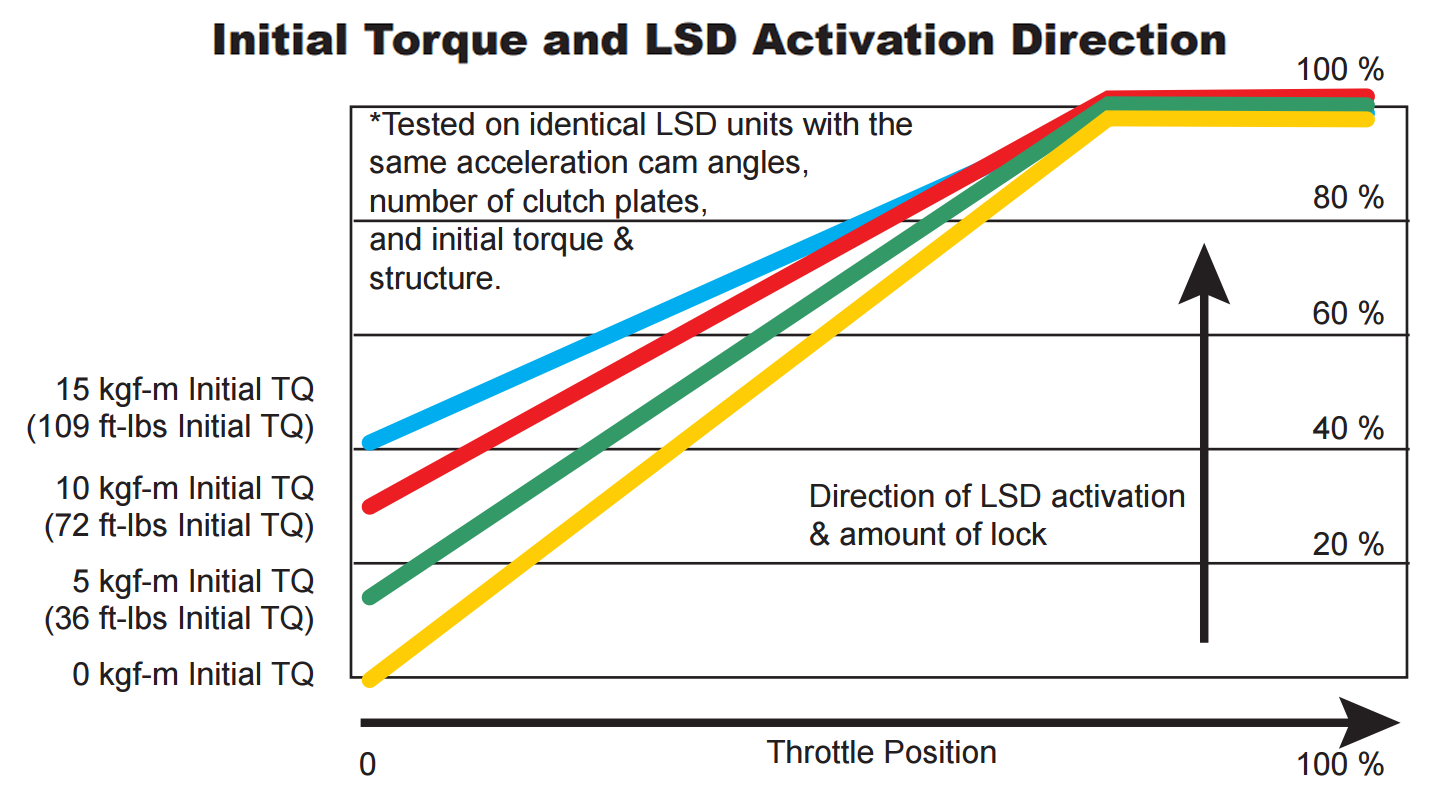

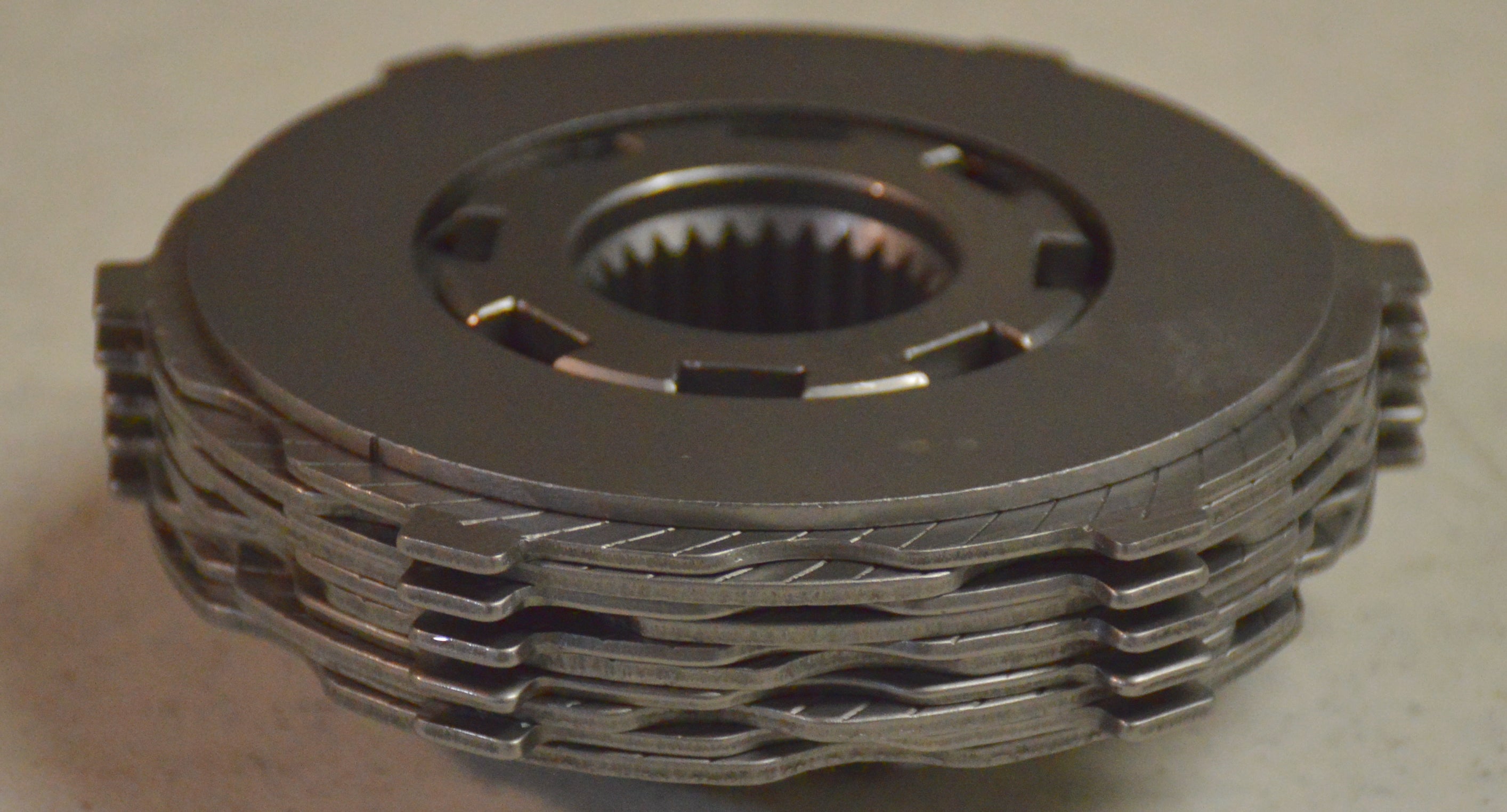

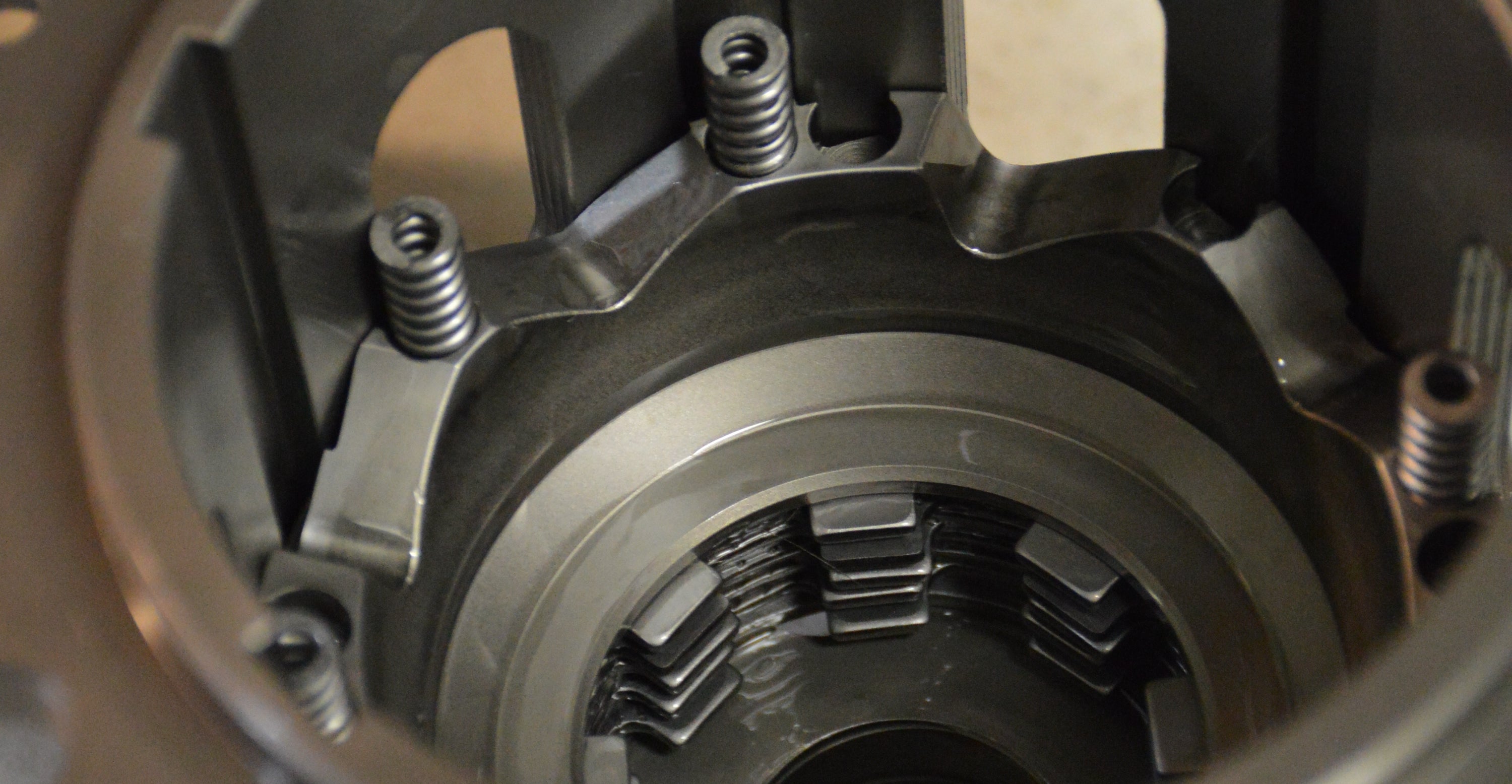

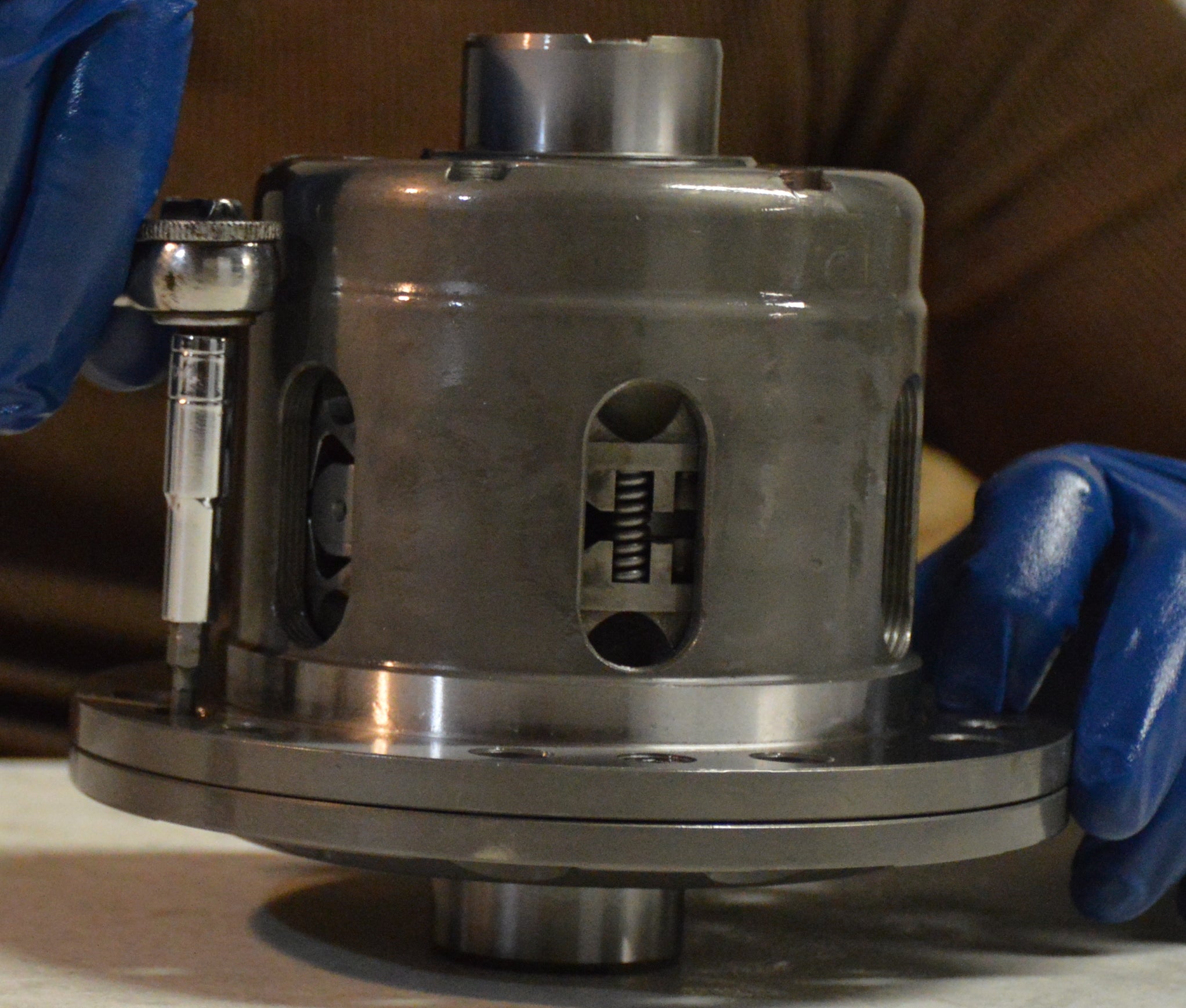

Finally, the Cusco RS is unique in that it uses coil springs rather than cone springs to apply preload tension to the clutch pack. Springs can be added or subtracted to manipulate the amount of preload, which is what determines how much throttle is needed to provoke the diff into locking up.

We knew we wanted 1.5-way locking action for sure. This was an easy decision to make as the reduced deceleration drag of the 1.5-way makes for reduced power-off understeer: perfect for a street car. The 2.0-way full banana is unwieldy under partial or no power and best suited to more extreme applications such as competitive drifting. In contrast, notice how the 1.5-way is considered suitable for the widest range of applications:

©Cusco USA

©Cusco USA

The clutch disks were also a simple choice. Fewer activated disks means less tendency for the car to kick the tail out under power. Deactivate one set of drive and driven disks for %80 maximum lock and two sets for %60. This can make for faster lap times depending on grip and power levels, but we think it would be less fun. We would prefer for our car to kick into a slide when hucked at a corner and given a bootfull of power; a-la old school M3s. So we chose to activate all twenty clutch disks, allowing for %100 locking capability.

Cusco themselves say that the number of activated clutches makes a “profound” difference in the characteristics of the diff. Just this one setting can give you completely different driving sensations.

©Cusco USA

The toughest choice was in the springs. More spring pressure means more preload, or Initial Torque, which makes for more aggressive handling characteristics. This makes the car more easily provoked, requiring a smaller amount of throttle input to begin locking up the rear wheels. On one hand we kindof like this idea, especially given that the traction and stability control will still stop the car getting out of hand in bad conditions and/or with less experienced drivers. Then again we like both drifting and grip driving, so we don’t want a car that slides so easily it can’t carry at least some speed on corner exit.

In the end, we decided to go with the minimum amount of spring tension by using six springs. We reasoned that, because we activated all the clutches, %100 lock would still be achievable with low spring pressure. We would just have to use more power to achieve full lock; a compromise we were totally at peace with.

!!! UNKNOWN HEADER TYPE (MULTI-LINE BREAK?) !!!

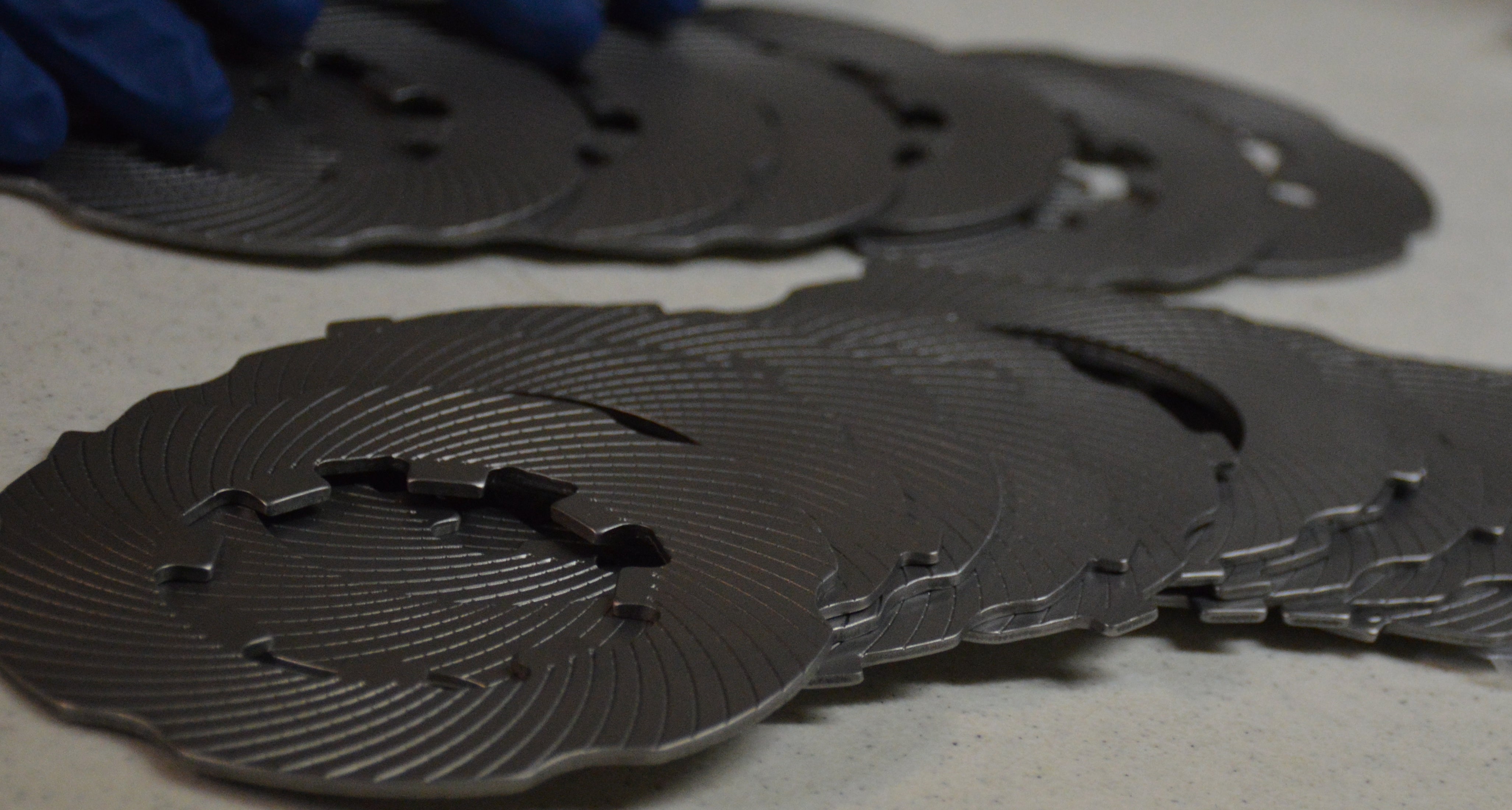

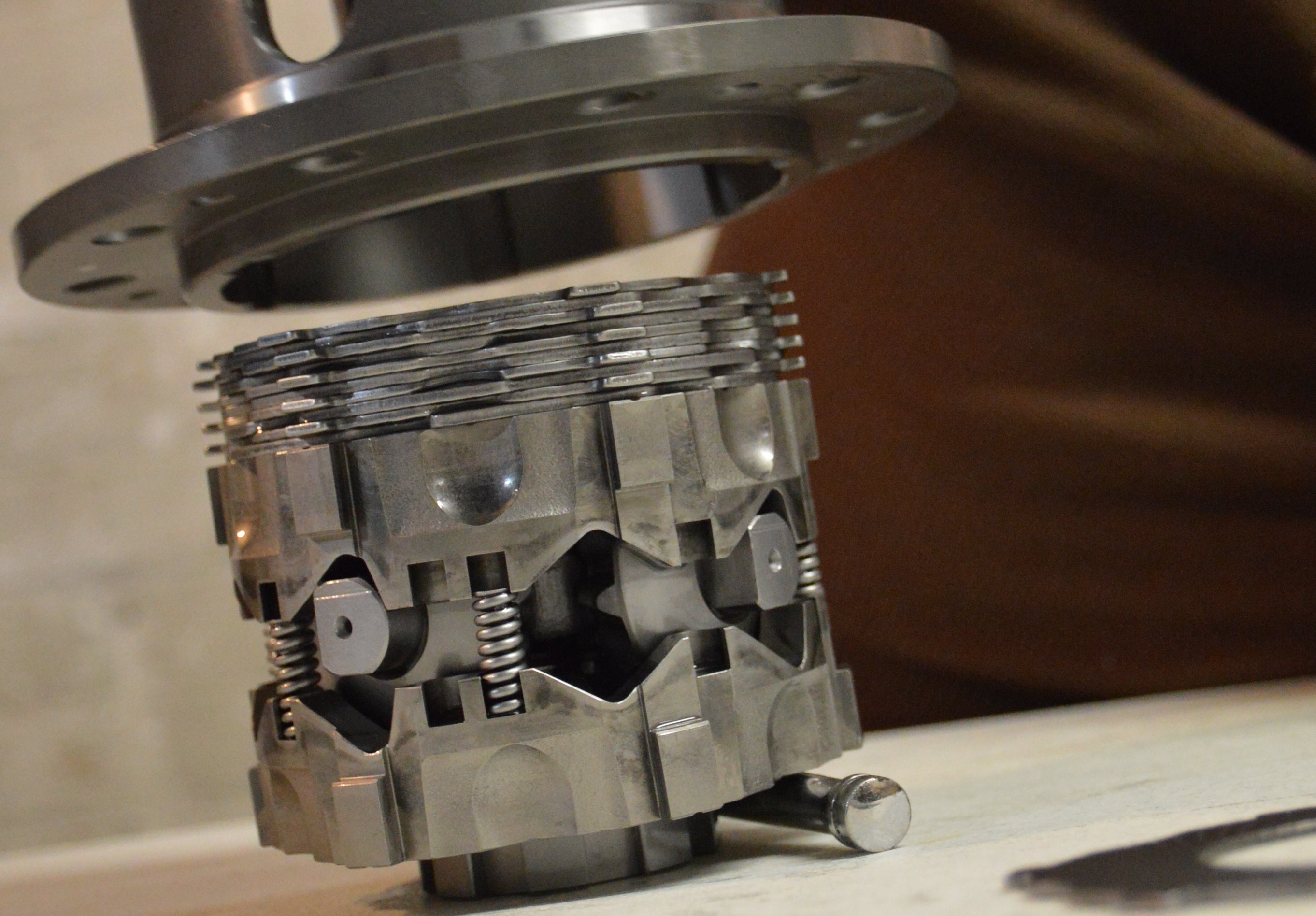

Our Cusco RS as returned from WPC treatment was pure motorsport pornography. The incredibly detail-oriented nature of the folks who run WPC shone through in the packaging of the returned parts.

Everything was beautifully wrapped in perfectly sized, heat-sealed plastic bags. The plastic was thick, resilient, and clearly quality stuff. Each parceled component even got a little strip of WPC logo’d tape.

Nice.

We especially loved the cute little envelope they made for our springs:

What an

adorable

faff. We’d have just dropped them in a zip-lock bag and been done with it. Guess that’s why we don’t work in a world-class metal-improvement facility.

Alright, enough with admiring the bags. Onward and inward!

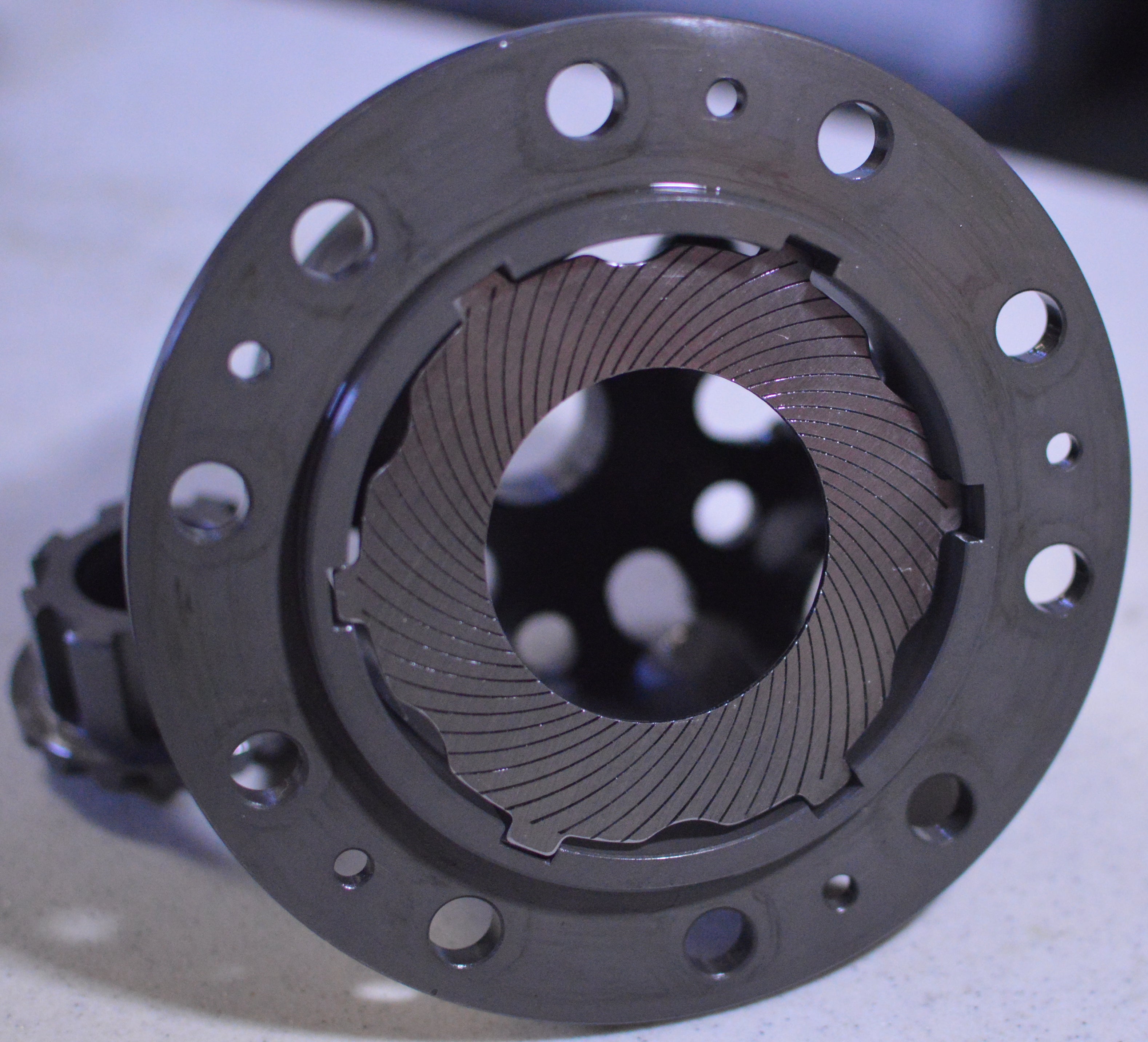

The outer case is a sight to behold. It is shockingly dense and difficult to lift. Forged from Chrome-Moly Steel, this hunk of metal is packed with technology. The quality of the fabrication absolutely shines through. The case rings like a bell when struck, producing an impressive amount of bounce-back:

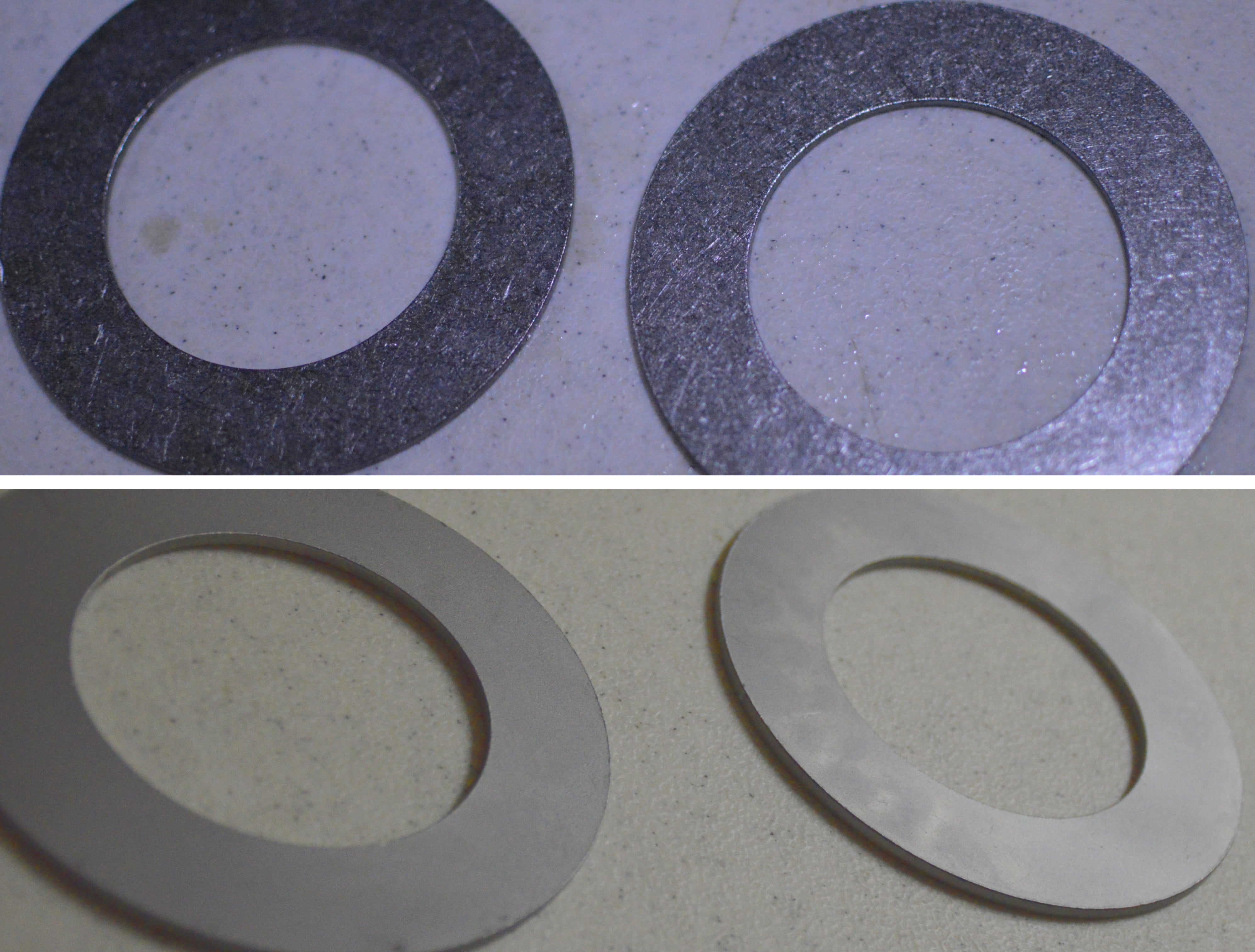

The rest of the parts are just as gorgeous. The WPC process has imbued every surface with a smooth, milky luster. This change is most apparent on the spacer rings.

!!! UNKNOWN HEADER TYPE (MULTI-LINE BREAK?) !!!

!!! UNKNOWN HEADER TYPE (MULTI-LINE BREAK?) !!!

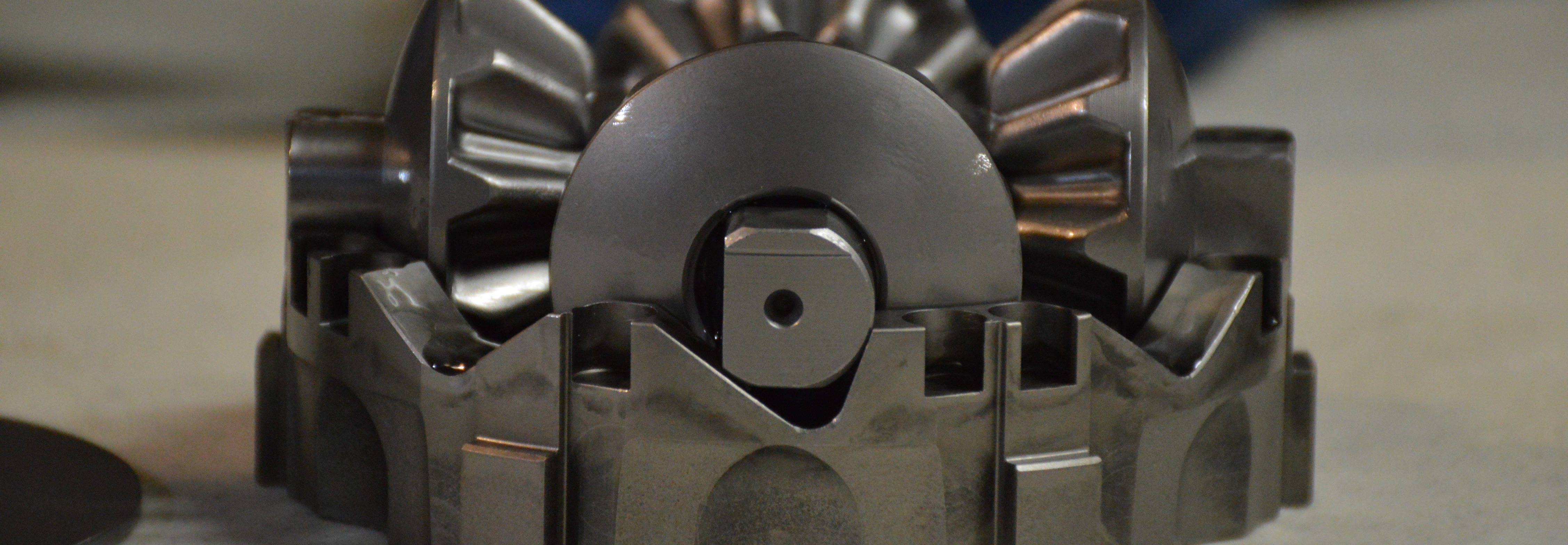

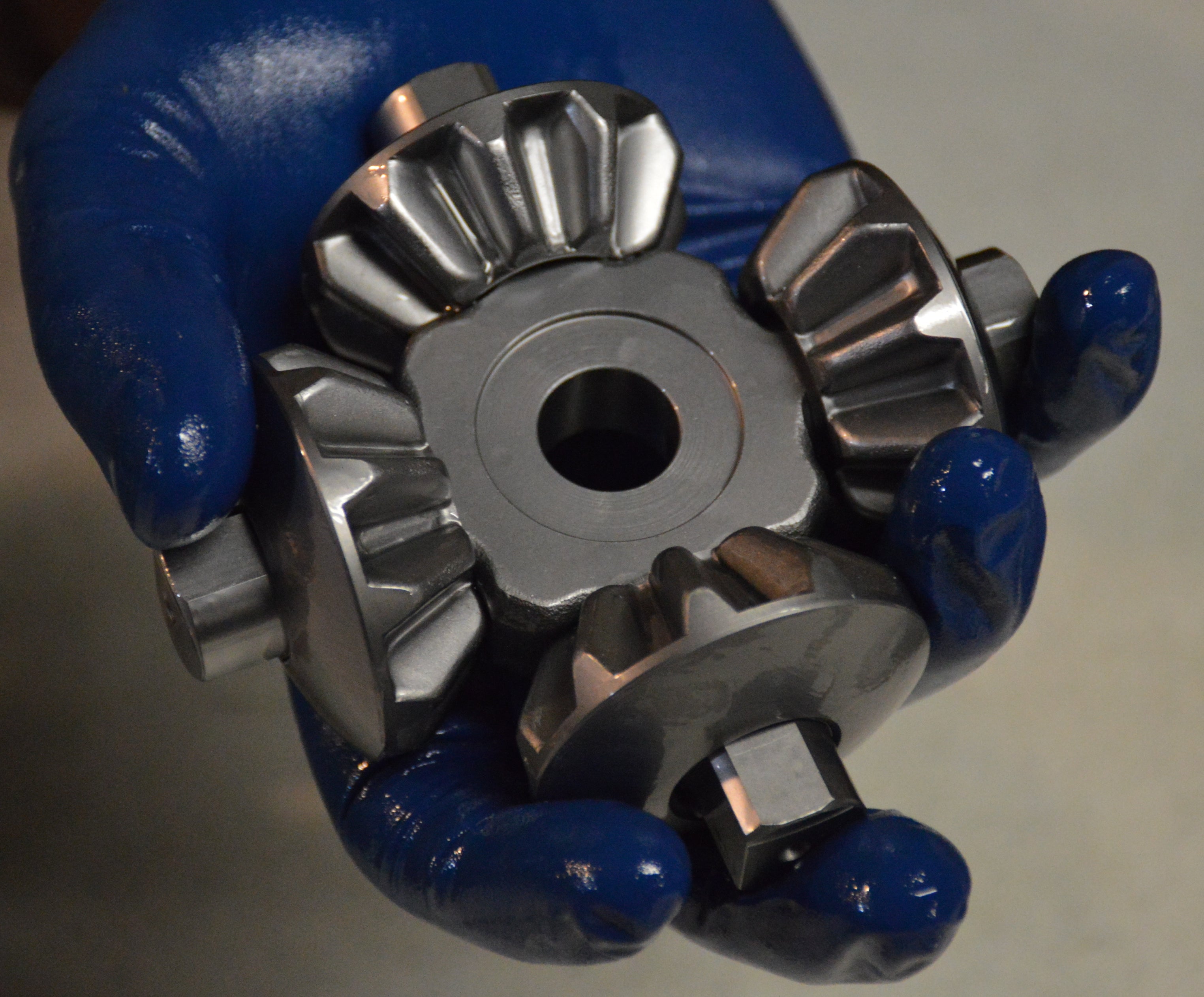

The treated parts just

feel

special. We wish we could have a copy of these spider gears to sit on our desk. It was incredibly pleasing just rolling the things over in our hand. Somehow, the strength of the little cold-forged gears felt palpable between our fingers.

No rest for the wicked though, these little gears had a lot of work to do. However, before final assembly it’s worth taking some time to look more closely at them, and the other parts, so we can get a better feel for how the Cusco RS really works.

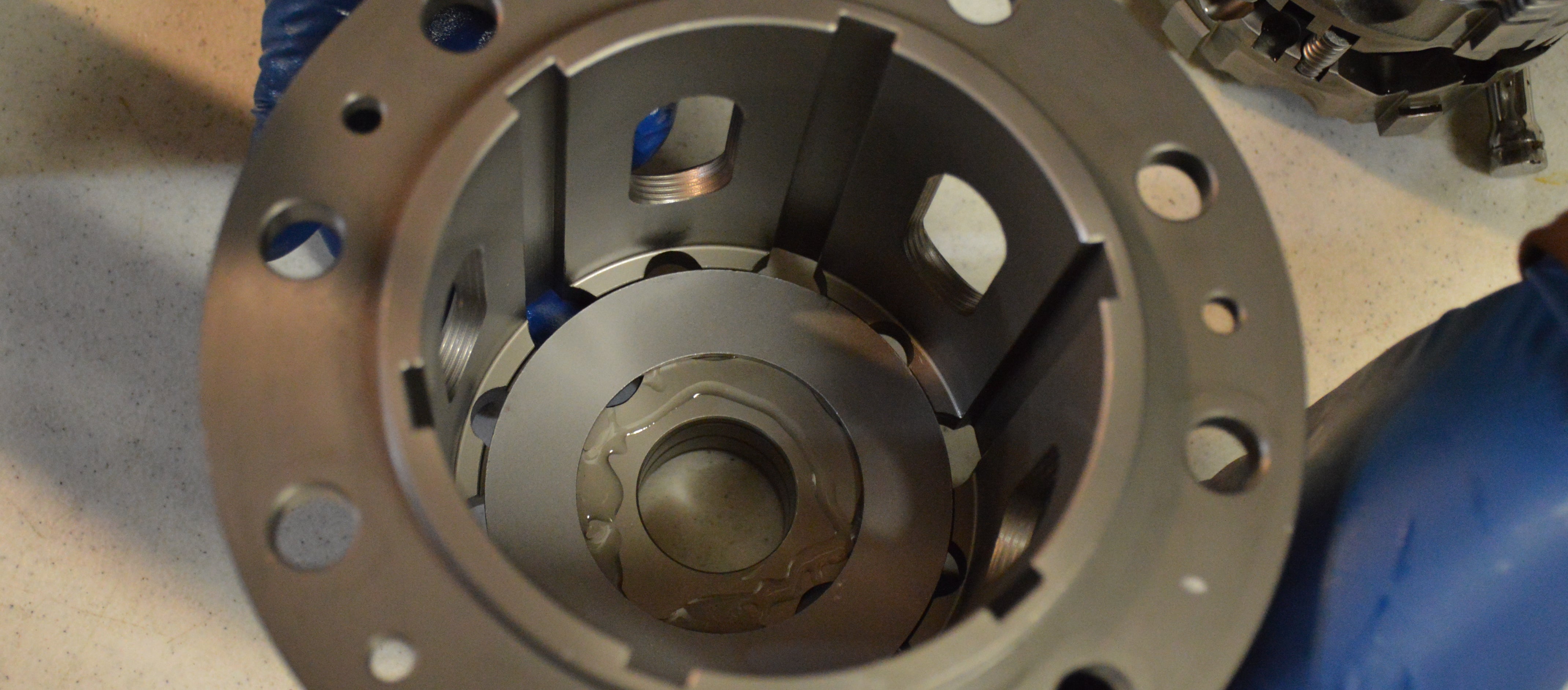

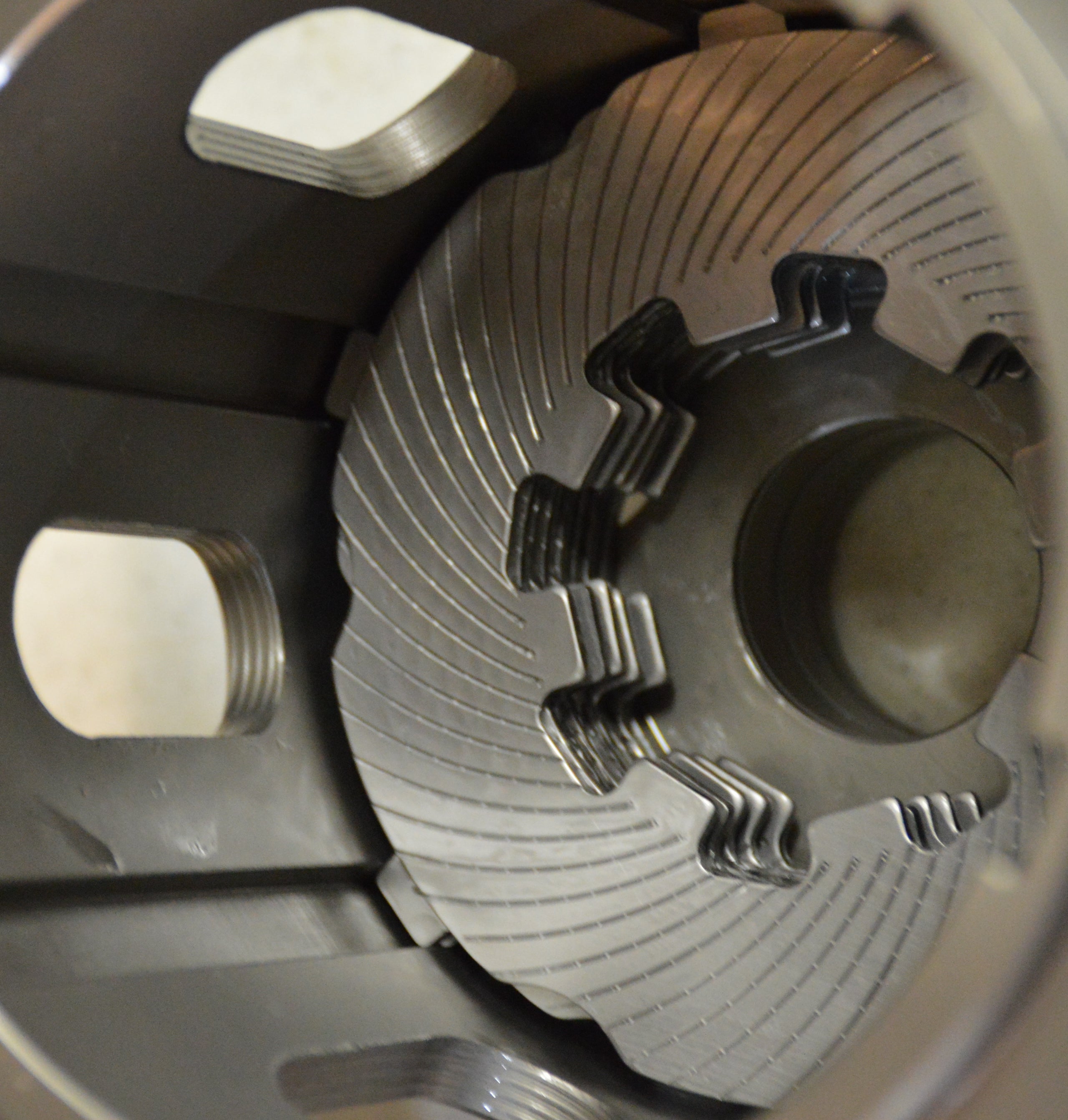

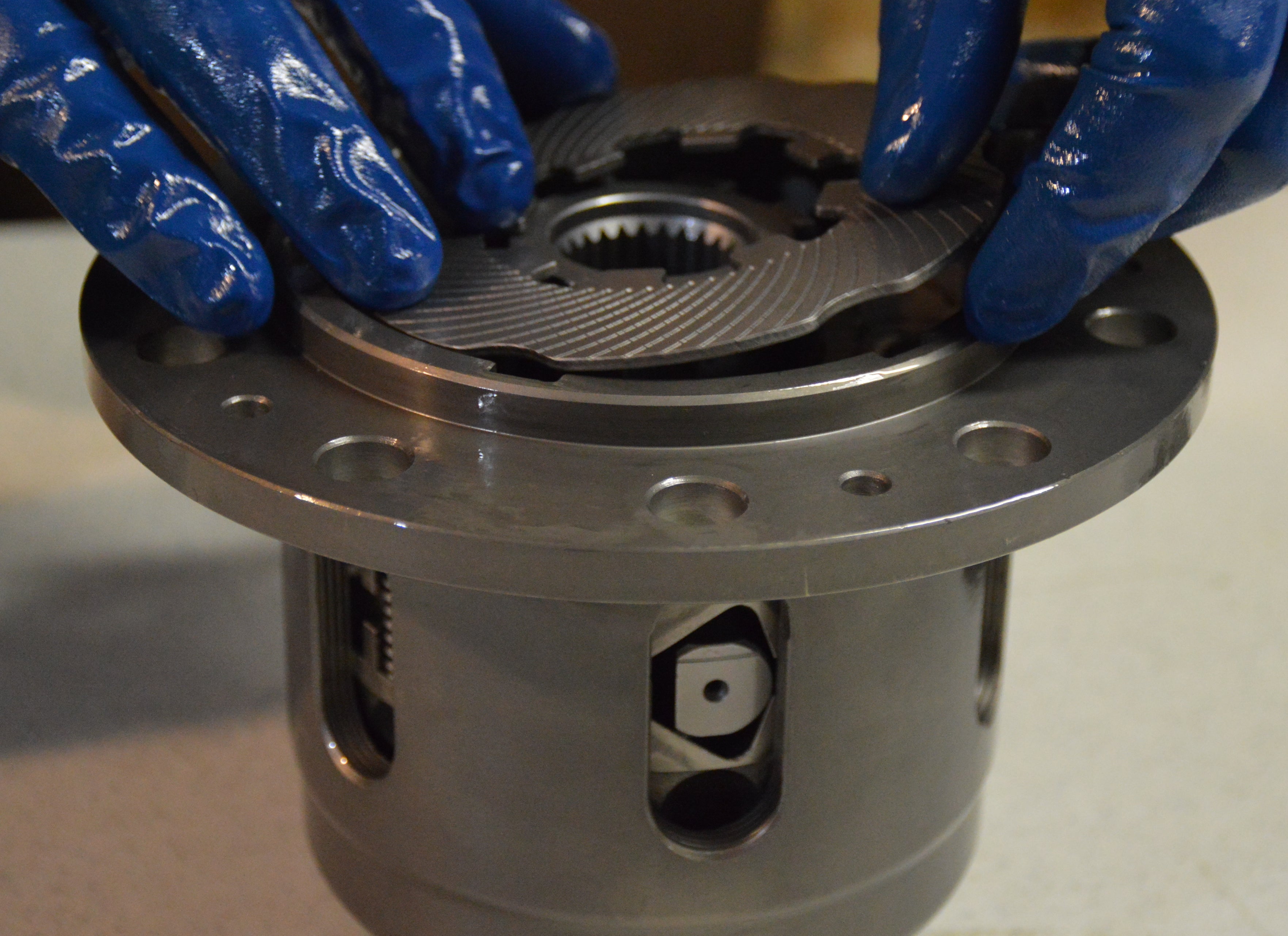

Our beloved horsepowers enter the differential housing via the pinion gear. This drives the ring gear which is bolted to the flange on the outer case of the diff, seen here. Many of the diff’s components are keyed into deep grooves inside the case. These are the “drive” components. Meshed against them are the “driven” components which are keyed to the output gears and do not make direct contact with the outer case.

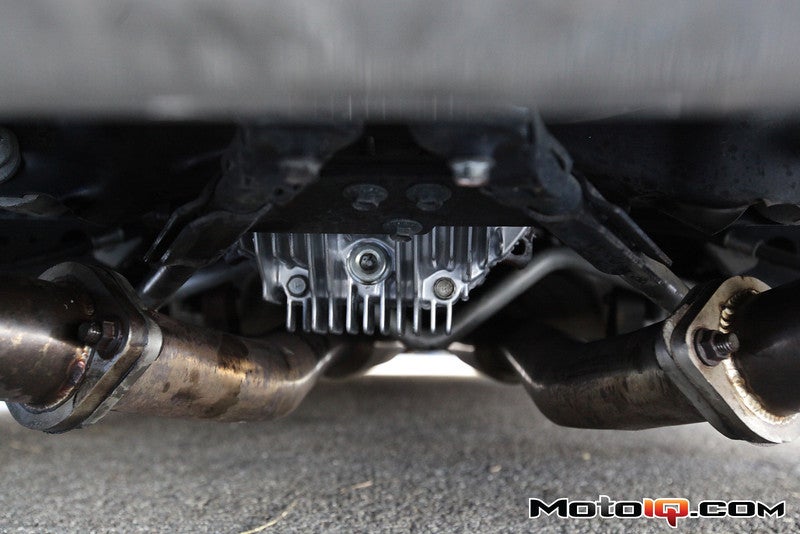

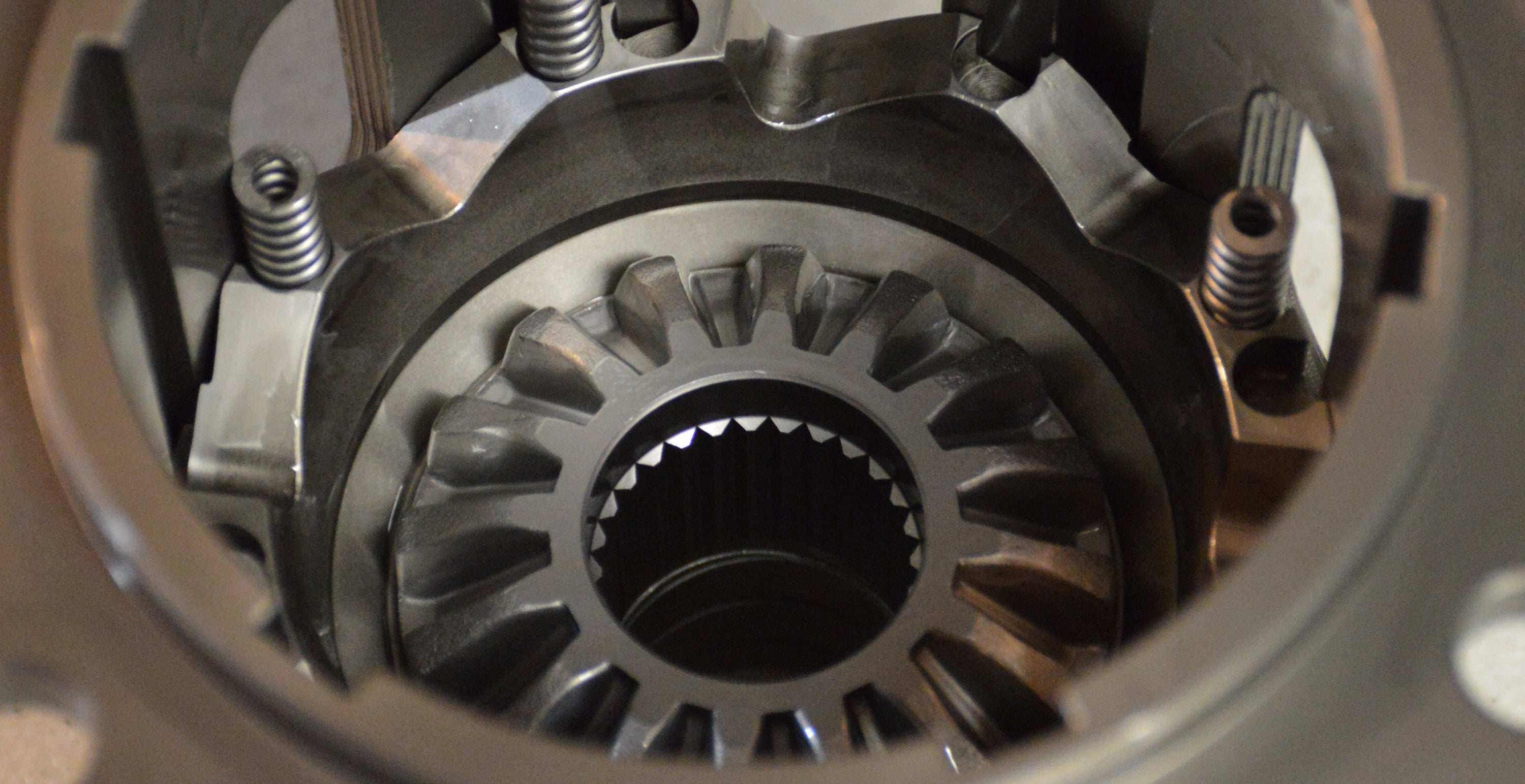

Engine power flows through the ring and pinion, the outer case, then into the center section. The center section has two halves which are keyed into the case by generous standoffs. These halves contain the “ramps” which drive the spider gears via the cross shaft:

When drive torque increases, the wedging force of the cross shaft against the ramp angles forces the two halves of the center section away from eachother. This causes them to squeeze outward on the clutch packs.

Meanwhile, some power is flowing into the drive clutches which are also keyed into the case. Under low torque conditions the drive clutches turn relatively freely against the driven clutches, transferring little power. The only friction between them in low torque states is made by preload forces generated in the springs.

When drive torque increases, the clutch packs truly go to work. As the center section starts to clamp down on the clutch packs a greater percentage of the power is transferred through them. This reduces the differentiation factor of the planetary section as more and more power is routed around the spider gears and straight into the output gears via the clutches. %100 lock occurs when virtually no power is being transferred through the spider gears. When all twenty clutch disks are activated, the Cusco RS is capable of routing all the engine’s power to the drive wheels via the clutch packs:

This is

serious business

on a street car. Only the most aggressive OEM limited slip differentials are capable of this feat and, as far as we know, all the modern ones are electronically assisted.

As badass as the assembled core of the Cusco RS looks, it’s pretty much impossible to slide into the case this way.

The core needs to be dropped into the case one piece at a time. So we strip everything back down and start properly.

First in is the spacer ring:

It is followed by the first drive clutch:

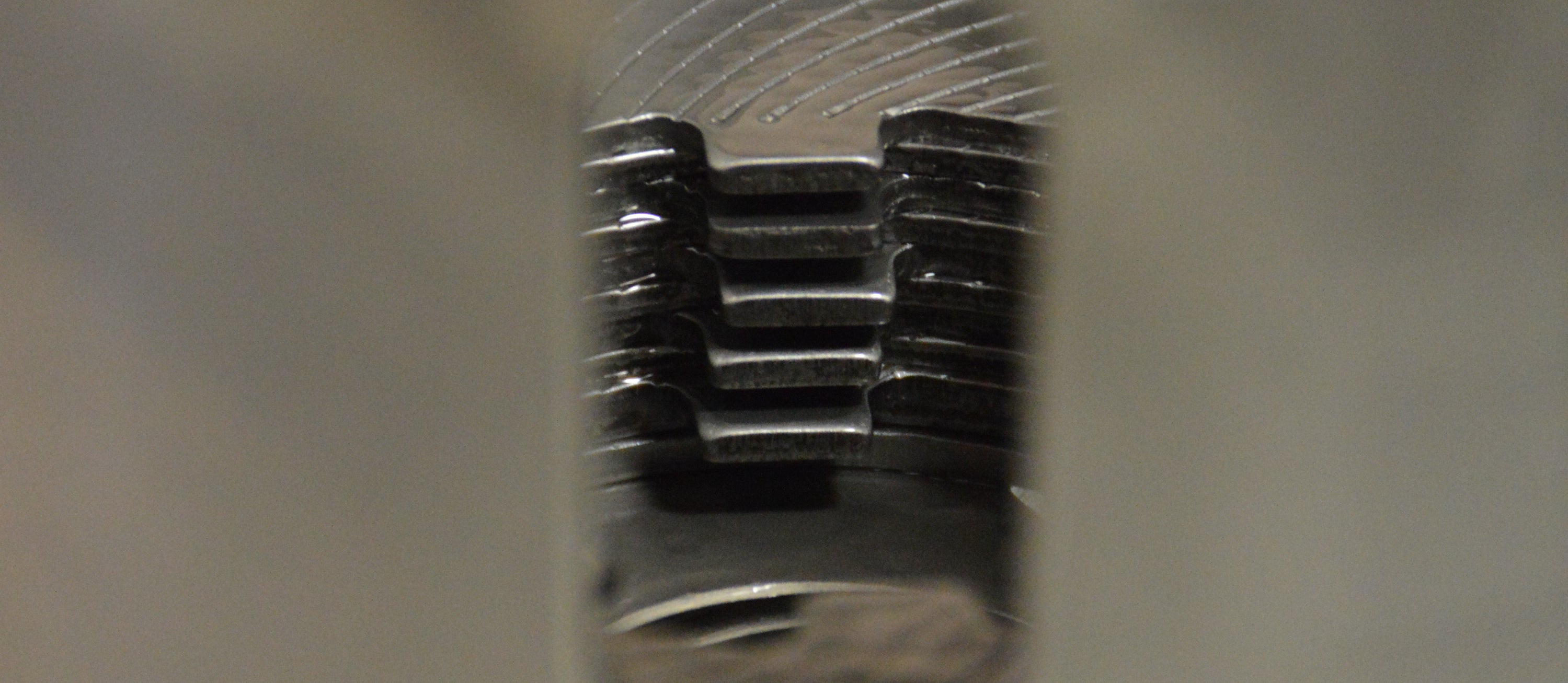

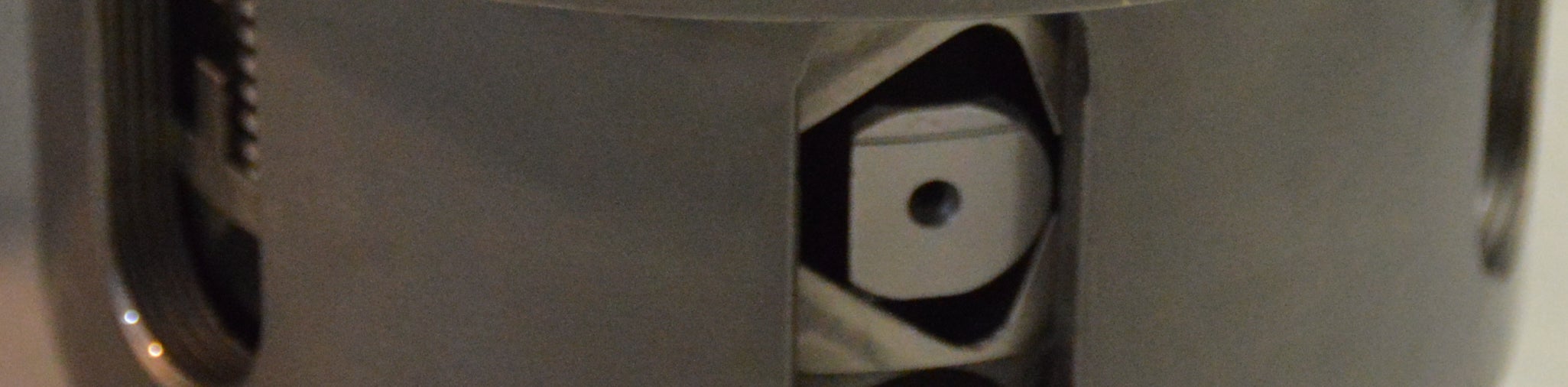

After that comes the first driven clutch. We alternate from drive to driven, taking care to ensure that the inner tabs of the driven clutches stay lined up. You can get a really good look at them through the outer windows in the case, like so:

If we wanted to deactivate some of the clutches, we would simply break the pattern to pair two driven clutches and two drive clutches together.

This can be done with up to eight of the ten clutches, effectively giving the diff twelve clutch disks and a maximum locking factor of %60.

Forget that though! We paid for 20 disks and we’re gonna use ‘em.

Complete with a hair, courtesy of our glamorous photographer/girlfriend who was responsible for all these pornagraphical photos.

Now comes the first half of our center section. As you can see we followed that up with the springs, but we should have waited till after the first output gear and the planetary gear set was in. Next up, the tabs

on the first five driven clutches all slip neatly into slots on the output gear:

In comes the planetary gearset. It gets pre-assembled and dropped in.

This is a very important step as the placement and orientation of the cross-shaft are responsible for setting the lock factor of the diff to 1.5-way or 2.0-way.

Here’s the position for 1.5-way, the one we want:

Very conveniently, two ends of the cross-shaft are always visible through two of the windows in the case. This makes it easy to double-check your settings before installing the diff.

From here it is very straightforward. We just do what we did on the other side in reverse, starting with a driven clutch and alternating from there. Soon everything is packed in and it’s time to shut the lid on this baby.

The two halves of the case bear witness marks which must be aligned.

This process can’t be rushed as the lid has an inner radius that fits very tightly against the case.

Care must be taken to make sure the lid is clocked correctly before snugging it down. The holes need to line up

perfectly.

You’ll know you’ve got it close enough if the bolts thread in easily by hand.

The springs will prop up the center section and make it slightly too large to fit in the case, as seen above. While tightening down the lid, you need to snug each bolt a little at a time so that the lid can slowly compress the center section on its way down. This means you can forget trying to use a screwdriver. Get the right size allen bit and drop it in a 1/4 inch ratchet wrench.

And there she is! Having the diff fully assembled caused us to tingle with anticipation. We couldn’t get it installed into the car quickly enough. Preparations had been made, but there’s more to a diff swap than just adding a new gear carrier. We needed to sort out the details, preferably before we had our car all taken apart.

In the end, we weren’t able to predict every single small item we would need to complete the swap. See what tripped us up on !!!error: Indecipherable SUB-paragraph formatting!!! of !!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

ESSSIX GmbH - Accountant/Wagon Thumper

> Zachary Oberle

ESSSIX GmbH - Accountant/Wagon Thumper

> Zachary Oberle

07/26/2016 at 12:59 |

|

This is good OPPO. Cant finish reading it now, you know the whole work thing, but I will tonight!

FTTOHG Has Moved to https://opposite-lock.com

> ESSSIX GmbH - Accountant/Wagon Thumper

FTTOHG Has Moved to https://opposite-lock.com

> ESSSIX GmbH - Accountant/Wagon Thumper

07/26/2016 at 13:26 |

|

Seconded. Don’t have time to read at work. Excited to read at dinner.

RallyWrench

> Zachary Oberle

RallyWrench

> Zachary Oberle

07/26/2016 at 13:29 |

|

It’s a thing of beauty. Great writeup, thanks. You should probably tag it NSFW though, this is pretty pornographic.

AMGtech - now with more recalls!

> Zachary Oberle

AMGtech - now with more recalls!

> Zachary Oberle

07/26/2016 at 15:57 |

|

Someone pass me a tissue

Zachary Oberle

> AMGtech - now with more recalls!

Zachary Oberle

> AMGtech - now with more recalls!

07/26/2016 at 16:26 |

|

Because the article brought a tear to your eye?

Zachary Oberle

> RallyWrench

Zachary Oberle

> RallyWrench

07/26/2016 at 16:27 |

|

Post has been tagged “Pornography” in honor of popular sentiment.

AMGtech - now with more recalls!

> Zachary Oberle

AMGtech - now with more recalls!

> Zachary Oberle

07/26/2016 at 17:54 |

|

Yes. Exactly. I’m very emotional.